Our Services

We place professionalism and skill at the core of our work and are committed to providing our services with the highest levels of efficiency. We ensure that our work is executed with high skill in all projects and processes, guaranteeing excellent results and customer satisfaction. We perform the following tasks with high professionalism and quality...

WELDING FOR PIPING & PIPELINE

Pressure welding must follow approved procedures, ensuring welds are uniform and free of defects. Welding is prohibited if the base metal temperature is below 15°C.

Thermal Treatment

Thermal Treatment are Required to ensure suitable Weld Integrity and will typically prevent or remove Undesirable Characteristics.

Sandblasting and Painting

Sandblasting and painting create harmful waste that can pollute water. Improper disposal violates procedures,and generators must manage hazardous materials like tributyl tin (TBT).

Design and Installation of Hangars

Hangar design and installation are crucial for aircraft safety, focusing on capacity and structure to provide a secure operational environment.

Radiographic Testing

Radiography inspects various materials,detecting defects like corrosion with minimal prep. TMI NDT Services provides safe, high-quality radiographic services for shop and field applications.

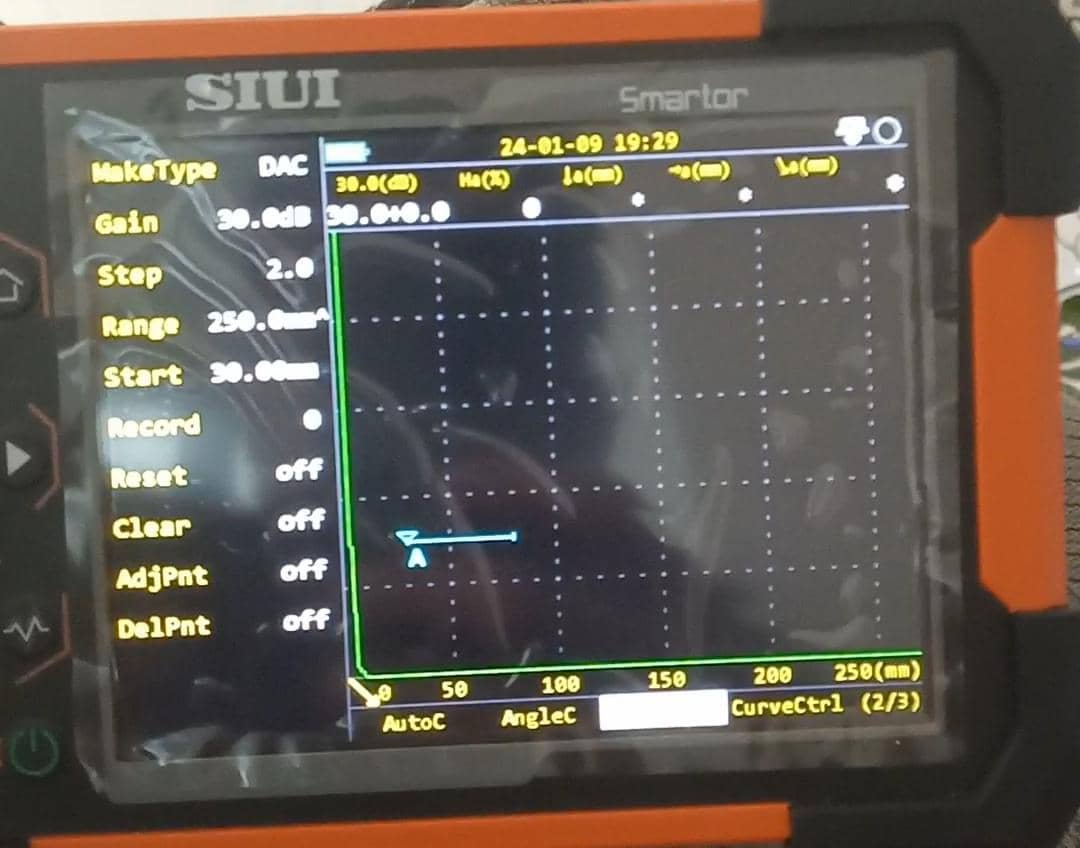

Ultrasonic Testing

It detects sub-surface defects and maps corrosion (thickness measurement), typically assessing material integrity in semi-products and welds .

Magnetic Testing

Used to detect surface and near-surface defects in ferrous materials, this method is popular for steel butt welds. Other applications include bolt thread inspection and propeller shafts .

Liquid Penetrate Testing

Liquid Penetrant Inspection (LPI) detects surface defects in non-porous materials, mainly in castings and welds. Magnetic particle inspection is preferred for ferrous materials .

Visual Testing

This method detects surface defects in non-ferrous materials, requiring no power source. It is portable and efficient, used where magnetic particle testing is not applicable .

QUALITY ASSURANCE

Quality assurance (QA) ensures products meet quality standards, enhancing customer satisfaction and reducing costs through metrics, Agile methodologies, and defect analysis .

National Cement Company

OUR ACHIVEMENT IN QUALITY ASSURANCE (National Cement Company مصنع اسمنت الوطنية)

SEPOC FIELD DEVELOPMENT

OUR ACHIVEMENT IN QUALITY ASSURANCE (SEPOC FIELD DEVELOPMENT)

SAFER TANKER

OUR ACHIVEMENT IN QUALITY ASSURANCE ( SAFER TANKER)

EXPORT LINE

OUR ACHIVEMENT IN QUALITY ASSURANCE ( BLOCK-5 TO BLOCK-4 EXPORT LINE)

JANAH HUNT COMPANY

OUR ACHIVEMENT IN QUALITY ASSURANCE ( JANAH HUNT COMPANY)

AL-UQLAH, S2

OUR ACHIVEMENT IN QUALITY ASSURANCE ( AL-UQLAH, S2. )

Welding Fabrications

Work will follow ASME B31.3 and good practices by qualified personnel. Documentation will be maintained, and materials must meet the specified piping class.

Our Services

Experts in providing these services for many years.

About Us

All Directions Company SERVICES

The purpose of our obligation is to describe the steps & precaution to be followed during weld joint fit up, alignment of piping and welding of joints of pipeline / pipe, its fittings & valves. The procedure is applicable for mechanical works of piping & pipeline jobs. The purpose of this procedure is to provide guidelines to reduce potential overexposure to noise/chemicals. This procedure applies to All Directions company facilities and work locations where welding, fabrication, erection, sandblasting and Painting works are being carried out, and to the employees carrying out all mentioned activities. We can provide NDT if its required, Generally we add value to the pressure equipment and structural industry to ensure best practice testing solutions to insure quality assurance during new fabrications, in-service inspections, repairs and modifications.

Why choose us?

We possess qualities that inspire confidence in our services.